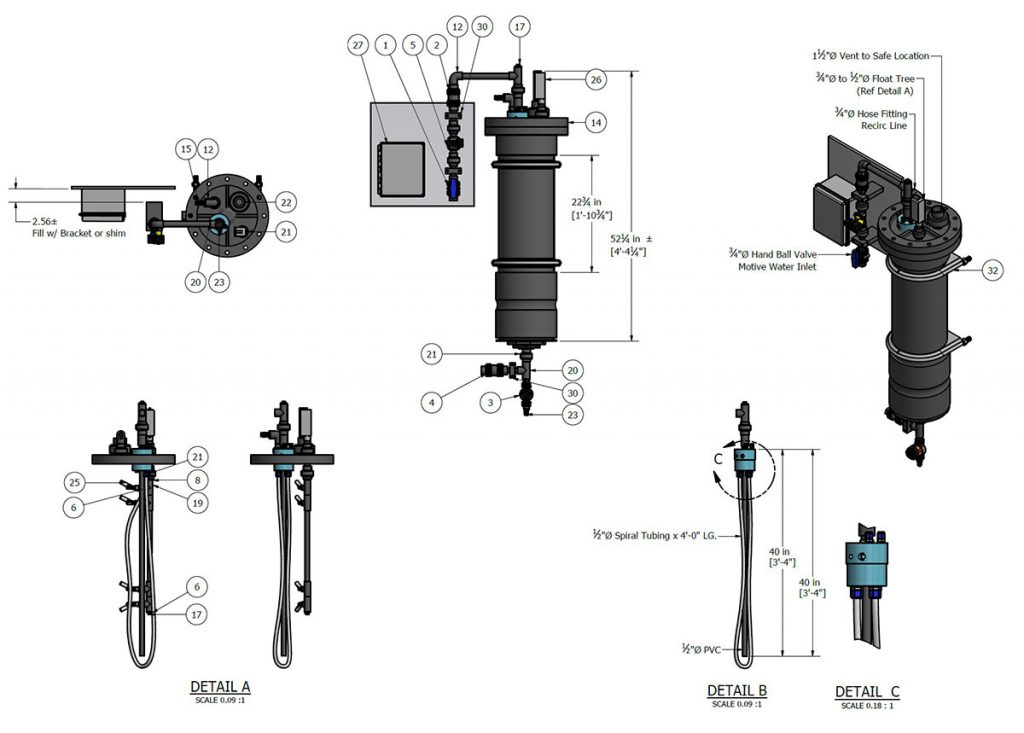

ADOX™ MiniACT Generator

Produces 0.5 to 30.0 lbs/day of ClO2

The ADOX™ MiniACT incorporates the learnings gained over 70 years of developing safe, reliable, and easy-to-operate chlorine dioxide (ClO2) generators. The ADOX™ MiniACT generator utilizes a vacuum base eductor that is integrated into a small, on-demand tank to safely and cost-effectively generate and deliver chlorine dioxide solutions. The ADOX™ MiniACT allows you freedom in your selection of application dosing pumps or eductor systems to safely deliver the ClO2 solution from the integrated tank into both low volume and high-pressure applications.

The ADOX™ MiniACT chlorine dioxide generator utilizes standard 7.5% sodium chlorite and 10-15% hydrochloric acid reaction chemistry to efficiently generate up to 30 pounds per day (PPD) of ClO2. The inherently safe eductor-based design is operated by the presence of water flow. The production rate into the ADOX™ MiniACT can be adjusted via rotameters, while the solution delivery can be adjusted via a 4-20 mA plant flow signal, dose setpoints or manually configured depending on the selected application dosing pump.

Easy Installation

The ADOX™ MiniACT is engineered to be installed in a continuously running process water line or a slipstream of that line back to the basin.

- 3/4″ water inlet with minimum 2 GPM @ 40 PSI

- Two chemical containers with chemical wands to be placed at the same elevation of the generator within 5 feet of the generator

- The ADOX™ MiniACT is engineered to be on demand tank fill with several out of tank dosing options depending on site specific customer requirements