ADOX™ InLine Generator

The Next Generation In Chlorine Dioxide Production

International Dioxcide’s patent pending design integrates the highest levels of safety, functionality, and industrial robustness in a self-contained modular design that is easy to install and requires a small footprint.

The critical design principle in the ADOX™ InLine generator is the reaction and delivery of chlorine dioxide in a safe, reliable, and easy-to-operate manner. The ADOX™ InLine generator uses sodium hypochlorite (bleach) and hydrochloric acid to react with the precursor sodium chlorite to generate chlorine dioxide.

The ADOX™ InLine chlorine dioxide generator offers:

- Robust industrial design — needs minimal maintenance

- Precise dosage control — eliminates wasted chemical

- Patent pending design includes numerous built-in safety features

- Vacuum-based design, chemical feeds are never pumped

- Multiple operator modes

- Highly efficient reaction

- Wide production range

- NSF 61 certified

All ADOX™ generators are affordable, safe, and highly efficient systems that can typically be installed and operating in one to two days. A supply of potable quality water, precursor chemical feed lines, a chlorine dioxide application line, and a power feed are the only connections required for most ADOX™ InLine installations.

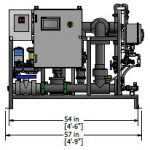

- Front

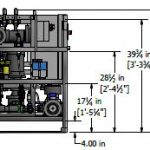

- Side

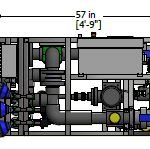

- Overhead

- Front