Municipal Plant Uses Sodium Chlorate/Hydrogen Peroxide Precursor for Chlorine Dioxide Production

Successfully treats 150 MGD of potable water

Situation

PurDOX™ BCD was successfully used to treat the water supply at a large Southeastern municipal drinking water plant that supplies 150 million gallons per day. PurDOX™ BCD is a drop-in replacement for a single proprietary sodium chlorate/hydrogen peroxide precursor feed used to generate chlorine dioxide (ClO₂) in small-scale water treatment applications.

International Dioxcide Inc., (IDI), an ERCO Worldwide Company, has been actively offering PurDOX™ BCD into industrial and municipal applications with great success since 2018. IDI partnered with a highly skilled water service provider to assist with the trial.

PurDOX™ BCD generates ClO₂ using the following reaction chemistry:

2 NaClO₃ + H₂SO₄ + H₂O₂ 2 ClO₂ + Na₂SO₄ + 2 H₂O + O₂(g)

In this process, the sodium chlorate and hydrogen peroxide components are pre-mixed into a single precursor solution that is reacted with sulfuric acid to generate chlorine dioxide. While PurDOX™ brand equipment is available directly from IDI, any third-party equipment designed for the small-scale sodium chlorate/hydrogen peroxide process has demonstrated seamless transition when switching over to PurDOX™.

In addition to the generator equipment, the PurDOX™ technology in many instances can use the same storage tanks, day tanks, metering pumps, and feed lines as other similar commercial formulations comprised of an aqueous solution of 40wt.% NaClO₃ and 7-10wt.% hydrogen peroxide.

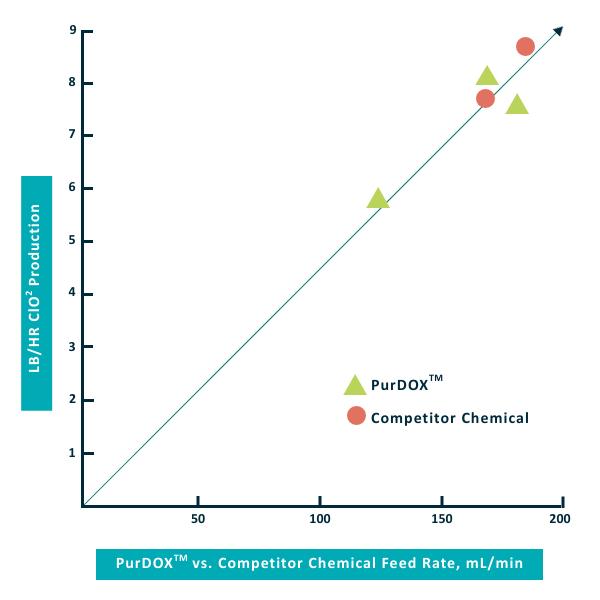

Figure 1. Measured ClO₂ production rate as a function of precursor solution feed rate. No significant deviation was observed when switching from the incumbent chemistry to PurDOX™.

Disinfection By-Product (DBP) Formation

Chlorite and chlorate by-products are the most common DBP’s formed from chlorine dioxide drinking water treatment application. The Maximum Contaminant Level (MCL) for chlorite in the United States is 1.0 mg/L and is typically monitored at various process locations to ensure compliance. Chlorate does not have an established MCL in the United States, but the World Health Organization recommends a limit of 0.7 mg/L. In this study, samples were taken not only at the plant but also after distribution to commercial operating sites where consumption is likely. As shown in Table 1, the residuals measured for PurDOX™ BCD were similar or lower than those measured from the incumbent technology.

| Incumbent Chemistry | PureDOX™ BCD | |||

|---|---|---|---|---|

| Sampling Location | Chlorite, mg/L | Chlorate, mg/L | Chlorite, mg/L | Chlorate, mg/L |

| Plant | 0.11 | 0.16 | 0.094 | 0.13 |

| Local Business | 0.078 | 0.19 | 0.047 | 0.12 |

| Local Hotel | 0.11 | 0.17 | 0.048 | 0.10 |

Table 1. Residual chlorite (ClO₂) and chlorate (ClO₃) concentrations measured at the plant effluent as well as sampling locations at a local business and hotel.

Conclusion

The results from the field trial conducted using PurDOX™ BCD to generate chlorine dioxide validated the excellent operability and efficiency of the technology. There was no statistically significant change in chemical usage and the treated water DBP residual concentrations were similar, if not lower, when compared to the incumbent chemistry. The PurDOX™ BCD precursor chemical utilized the existing customer-owned generation equipment at the site, without any operational or performance issues.